Resetting the control unit on your gate: when and why?

Sometimes the unexpected can happen (like violent storms which can lead to power surges or disconnections). In these situations, you might have to reset the control unit of the various gate and garage door automation units.

In other circumstances the electricity might unexpectedly fail precisely when the strokes are being memorised, causing the data to be saved only partially. In this case, a reset will be necessary and the control unit will have to be programmed again from the beginning.

These are only two quite commonplace examples to shine some light on an important issue. Under what circumstances is it necessary or advisable to reset the control unit of motors for gates or garage doors?

In this article, LIFE would like to give you some insight into what circumstances would commonly require a control unit reset, but we also would like to explain how to run checks to avoid these situations.

When to reset the automation device’s control unit.

Let’s start off by saying that a reset is necessary whenever something interferes with the system’s normal operation.

There are many factors that could affect the normal operation of the motors; even though power fluctuations are one of the most frequent causes, there are several other situations that could happen.

Another situation which could make it necessary to reset the control unit is when users decide to set their own time lag for the opening/closing of door leaves. In such a case, the previous parameters must be reset using the manual programming mode to set the new intervals with the remote control. Resetting is as easy as one-two-three with the Digital LIFE (DL) control unit: all you need to do is press the START button.

The advantages of programming a LIFE control unit

All programming operations on the control unit (both automated and manual) must always be performed by specialised technicians.

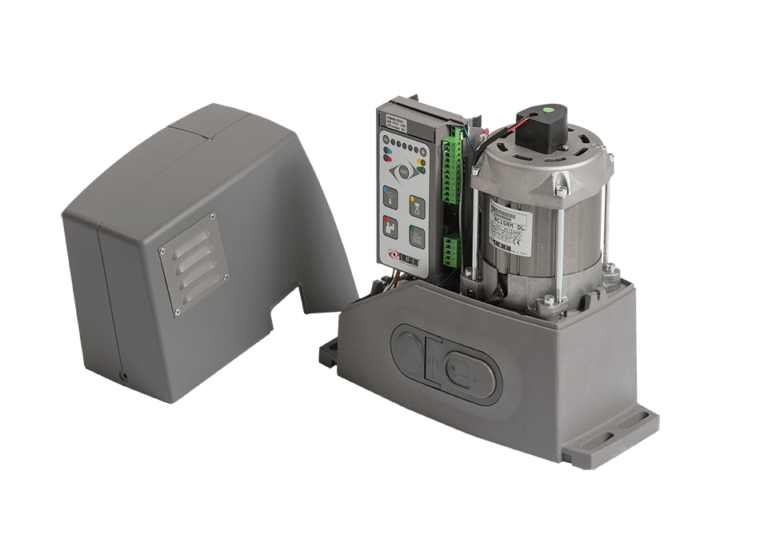

It is not just manual programming that’s quick and easy, because LIFE DL is the only control unit on the market that allows you to perform automatic programming in only one minute by simply touching the keypad!

Precisely this unique feature is the reason why LIFE is known and appreciated on the automation market both by installers (who know that installation work will be significantly easier and quicker) and end customers (who can rely on LIFE motors to enjoy the advantages of a robust automation system that delivers consistent performance over time while requiring minimal maintenance).

Apart from the situations that we looked at so far, as a general rule it is always important to clearly identify the causes that have prevented the system from working normally. Indeed, a reset should be seen as a last resort that the installer will rely on after carrying out all necessary checks.

This is because an automated system often cannot move due to a mechanical factor; this could be a rusty hinge, a poorly positioned rack or a damaged gate wheel. In each one of these cases, resetting the control unit would be absolutely pointless.

In any case, your local installer will be perfectly able to run all necessary checks to identify any obstructions or problems, after which he will decide the next step, and his task will be made all the easier by the reliability and ease of use of Life motors.